Slip casting is a versatile technique used in ceramics to create thin-walled ceramic objects. It involves pouring liquid clay, known as slip, into plaster molds, allowing for the production of intricate and delicate forms. This topic cluster explores the principles, techniques, and applications of slip casting, focusing on enabling thin-walled ceramic objects through this process.

Understanding Slip Casting

Slip casting is a ceramic forming technique that allows for the creation of thin-walled objects with complex shapes and intricate details. The process involves the following key steps:

- Preparation of the Slip: The slip used in slip casting is a liquid form of clay, which can be formulated with various additives to achieve desired properties.

- Mold Preparation: Plaster molds are typically used for slip casting. These molds must be properly prepared and treated to ensure the successful release of the formed ceramic object.

- Pouring the Slip: The prepared slip is poured into the mold, allowing for the liquid clay to evenly coat the interior surface of the mold.

- Draining and Drying: Excess slip is drained from the mold, leaving a layer of clay adhered to the mold's surface. The casting is then left to dry and form a solid shell.

- Demolding: Once the formed ceramic object reaches the desired thickness and consistency, it is carefully removed from the mold.

- Firing: The dried ceramic object is fired at high temperatures to achieve its final strength and appearance.

Enabling Thin-Walled Ceramic Objects

Slip casting offers unique advantages for creating thin-walled ceramic objects:

- Complex Forms: The fluid nature of slip allows for the reproduction of intricate and detailed forms, making it possible to create thin-walled objects with complex shapes.

- Uniform Thickness: By controlling the pouring and draining process, ceramic objects with consistent, thin walls can be produced, maintaining a uniform thickness throughout.

- Reduced Weight: Thin-walled ceramic objects are generally lighter in weight, offering practical and aesthetic benefits in various applications.

- Customization: Slip casting allows for the production of custom-designed thin-walled ceramic objects, offering flexibility for artistic and functional requirements.

Applications of Thin-Walled Ceramic Objects

The ability to create thin-walled ceramic objects through slip casting opens up a range of applications:

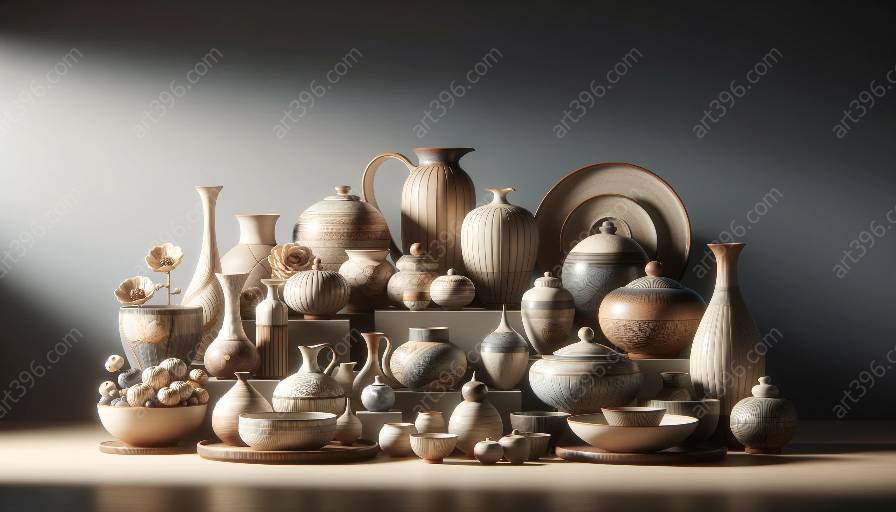

- Tableware and Vessels: Thin-walled ceramic objects are commonly used in the production of elegant tableware, such as dishes, bowls, and cups, showcasing delicacy and refinement.

- Art and Sculpture: Artists and sculptors utilize slip casting to create thin-walled ceramic objects for artistic expression, exploring the interplay of light, form, and texture.

- Lighting: Thin-walled ceramic lampshades and light fixtures offer a blend of functionality and aesthetics, diffusing light in unique and captivating ways.

- Architectural Elements: Ceramic panels, tiles, and architectural details with thin walls add a touch of sophistication and craftsmanship to interior and exterior spaces.

Enabling thin-walled ceramic objects with slip casting requires a deep understanding of the materials, processes, and design considerations. By mastering the principles of slip casting and its applications in creating delicate ceramics, artisans and designers can unleash their creativity and bring forth captivating, thin-walled ceramic masterpieces.