Slip casting is a versatile and widely used technique in ceramics that allows for the production of thin-walled ceramic objects with intricate designs and shapes. This process involves pouring a liquid clay mixture, known as slip, into a plaster mold to create hollow ceramic forms. Slip casting is favored for its ability to produce delicate and precise ceramic pieces, making it a popular method among artists and manufacturers alike.

The Process of Slip Casting

The process of slip casting begins with the creation of a plaster mold that corresponds to the desired shape of the ceramic object. The plaster mold is carefully prepared to absorb moisture from the slip while providing a suitable texture and finish to the final product. The slip used in slip casting is a liquid mixture of clay and water, often with added ingredients to enhance fluidity and adhesion.

Once the mold is prepared, the slip is poured into the mold, allowing it to coat the inner surfaces evenly. As the plaster mold absorbs water from the slip, a clay layer begins to form, gradually thickening to create the desired wall thickness. The excess slip is poured out of the mold after a specified period, leaving behind a layer of clay that will later be solidified into the ceramic form.

Enabling Thin-Walled Ceramic Objects

The unique advantage of slip casting lies in its ability to create thin-walled ceramic objects. This is achieved through the controlled absorption of water from the slip by the plaster mold. As the moisture is drawn out, the clay particles in the slip come together, forming a solid layer that takes the shape of the mold. The rate of water absorption and the composition of the slip play a crucial role in determining the thickness and strength of the ceramic walls.

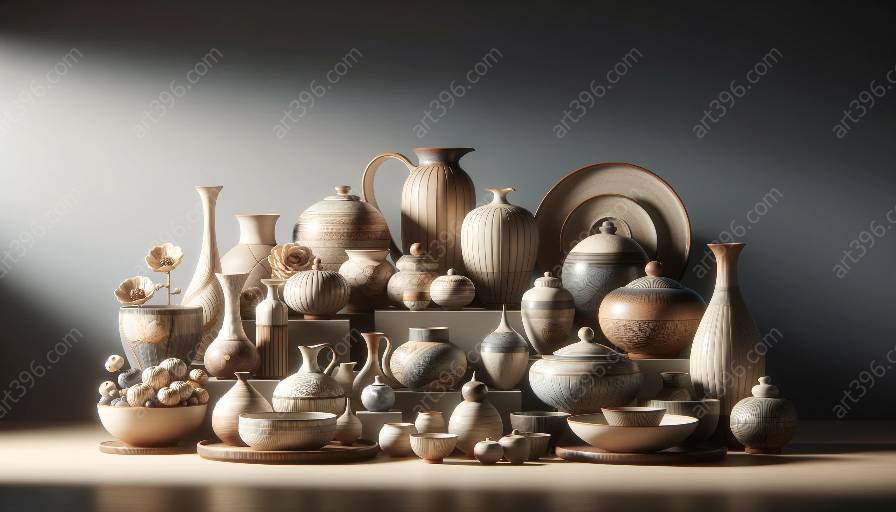

By carefully monitoring the casting process, artisans can achieve remarkable thin-walled ceramic objects with consistent thickness and intricate details. This capability to produce thin walls makes slip casting suitable for creating delicate ceramic items such as vases, decorative pieces, and intricate sculptures with fine, graceful contours.

Materials and Variations in Slip Casting

Various clay bodies and additives can be used to create slips tailored to specific design requirements. This flexibility allows artisans to fine-tune the properties of the slip, such as viscosity, shrinkage, and color, to suit the intended purpose of the ceramic object. Additionally, techniques such as multiple-part molds, surface treatments, and the incorporation of decorative elements further expand the creative possibilities of slip casting, enabling the production of unique and visually appealing thin-walled ceramic pieces.

Benefits of Slip Casting

Slip casting offers several benefits that contribute to its widespread use in ceramic production. One of the key advantages is the ability to replicate intricate designs and complex shapes with precision, making it an ideal method for mass production of identical ceramic forms. The process also allows for efficient use of materials, as the excess slip can be recycled, minimizing waste and contributing to a sustainable approach to ceramic manufacturing.

Furthermore, slip casting enables artisans to explore innovative design concepts, experiment with various surface treatments, and create thin-walled ceramic objects that embody elegance and finesse. The versatility and repeatability of the process make it suitable for both traditional and contemporary ceramic designs, offering artists and manufacturers a valuable technique for realizing their creative visions.