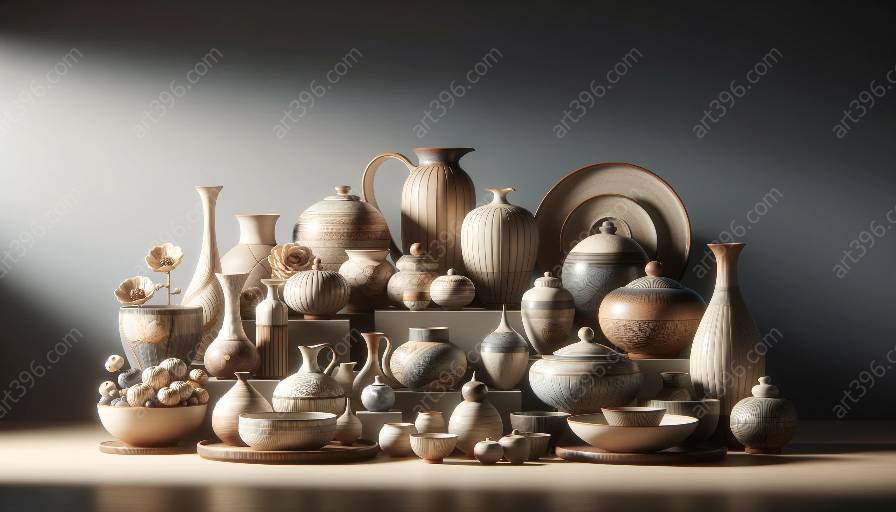

Commercial ceramics have undergone a significant transformation in recent decades, thanks to rapid advancements in technology. From advanced materials to cutting-edge manufacturing processes, these innovations have revolutionized the commercial ceramics industry, enhancing product quality, performance, and sustainability. In this comprehensive guide, we will explore the impact of technological innovations on commercial ceramics and how they are shaping the future of this dynamic industry.

Advanced Materials

One of the key areas of technological innovation in commercial ceramics is the development of advanced materials. Traditional ceramics, such as pottery and tableware, have been enhanced with the introduction of new materials that offer superior strength, durability, and aesthetic appeal. For example, advanced ceramics like zirconia and alumina are being used in commercial applications due to their exceptional mechanical and thermal properties. These materials enable the production of high-performance ceramic components for various industries, including aerospace, automotive, and medical.

Manufacturing Processes

In addition to advanced materials, technological innovations have also revolutionized the manufacturing processes in commercial ceramics. State-of-the-art techniques such as 3D printing, digital fabrication, and automated production lines have streamlined the production of ceramics, leading to improved efficiency and precision. Furthermore, the integration of smart manufacturing technologies, including Internet of Things (IoT) sensors and data analytics, has enabled real-time monitoring of ceramic production, ensuring consistent quality and reducing waste.

Nanotechnology in Ceramics

Nanotechnology has played a pivotal role in driving technological innovations in commercial ceramics. By manipulating materials at the nanoscale, researchers and manufacturers have been able to significantly enhance the properties of ceramics, such as hardness, chemical resistance, and electrical conductivity. Nanoceramics, for instance, exhibit remarkable mechanical strength and can be tailored for specific industrial applications, such as coatings, catalysts, and electronic devices.

Environmental Sustainability

Another significant aspect of technological innovations in commercial ceramics is the focus on environmental sustainability. Sustainable manufacturing processes, such as eco-friendly kilns and energy-efficient firing techniques, have minimized the environmental impact of ceramic production. Additionally, the development of recyclable and biodegradable ceramic materials has paved the way for eco-conscious product design, meeting the growing demand for sustainable solutions in the commercial ceramics market.

Futuristic Applications

The convergence of technology and ceramics has opened up exciting futuristic applications across various industries. From advanced ceramics used in 3D-printed implants to ceramic matrix composites for next-generation aircraft engines, the potential for technological innovations in commercial ceramics is virtually limitless. As industries continue to push the boundaries of material science and engineering, commercial ceramics will play a pivotal role in enabling innovative solutions for the challenges of tomorrow.