Integrating ceramics with other materials in product design presents a unique set of challenges and opportunities. From engineering complexities to aesthetic considerations, the fusion of ceramics with different materials requires a nuanced approach that balances functionality, durability, and design appeal. In this comprehensive topic cluster, we'll delve into the intricate world of ceramics in product design and explore the challenges, solutions, and innovative applications in this field.

The Versatility of Ceramics in Product Design

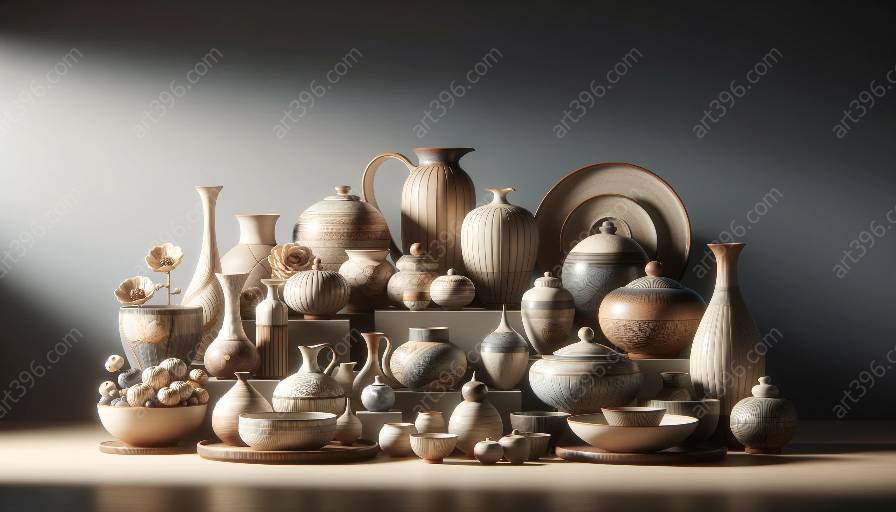

Ceramics have been an integral part of product design for centuries, owing to their remarkable properties such as heat resistance, hardness, and aesthetic appeal. Whether it's the elegant finish of a porcelain vase or the durable construction of ceramic cookware, the versatility of ceramics has made them a staple in various consumer and industrial products.

When considering the integration of ceramics with other materials, it's essential to understand the dynamic interplay between different substances. Ceramic composites, which combine ceramics with metals, polymers, or other ceramics, offer a wide range of properties and applications, but they also introduce a host of challenges that designers and engineers must navigate.

Engineering Challenges in Material Compatibility

One of the primary challenges in combining ceramics with other materials is achieving material compatibility and structural integrity. Ceramics are known for their brittleness and high compressive strength, which can pose challenges when integrated with more ductile materials such as metals or polymers. The stark differences in mechanical properties require meticulous engineering and material selection to ensure that the final product is both functional and durable.

Moreover, thermal expansion coefficients and chemical interactions between ceramics and other materials must be carefully managed to prevent delamination, cracking, or degradation over time. Designing products that can withstand thermal cycling, mechanical stress, and environmental exposure while maintaining the desired aesthetics demands a thorough understanding of material science and manufacturing processes.

Aesthetic and Functional Integration

Aside from the technical challenges, combining ceramics with other materials also involves a delicate balance of aesthetics and functionality. The visual appeal of ceramics often complements the tactile qualities of metals or the flexibility of polymers, offering designers a rich palette of creative possibilities. However, achieving seamless integration and harmonious design requires a deep appreciation for the nuances of each material.

For instance, in the domain of consumer electronics, the integration of ceramic components with metal or glass enclosures requires meticulous attention to detail, ensuring that the final product exudes elegance while meeting stringent performance standards. Similarly, in architecture and interior design, the combination of ceramic tiles with metal trims or wooden fixtures demands a holistic design approach that considers not only the visual impact but also the durability and maintenance requirements of the composite materials.

Advancing Ceramic Composite Technologies

Despite the challenges, ongoing research and innovation in ceramic composites have yielded remarkable advancements in material science and product design. From high-performance ceramic-matrix composites used in aerospace and automotive applications to the integration of ceramic nanoparticles in biomedical devices, the potential of ceramics in tandem with other materials is continually expanding.

New fabrication techniques, such as additive manufacturing and hybrid material processes, offer unprecedented opportunities to create intricate, multi-material products that leverage the strengths of ceramics alongside other substances. These developments underscore the importance of interdisciplinary collaboration between materials engineers, designers, and manufacturers in overcoming the challenges of combining ceramics with other materials.

Embracing the Future of Ceramics in Design

As the boundaries of material science and design continue to converge, the challenges associated with combining ceramics with other materials are giving way to innovative solutions and captivating design possibilities. Whether it's enhancing the performance of industrial machinery through ceramic-matrix composites or crafting cutting-edge consumer products that blend ceramics with advanced polymers, the fusion of materials represents a frontier where creativity and functionality intersect.

By understanding the intricacies of material compatibility, embracing advanced manufacturing techniques, and pushing the boundaries of traditional design paradigms, designers and engineers can unleash the full potential of ceramics in product design. The challenges are indeed formidable, but the rewards of creating products that seamlessly integrate ceramics with other materials are equally profound.