Ceramics have been integral to architectural design for centuries, offering unique opportunities for both aesthetic and functional applications. Understanding how the production process of ceramics influences their use in architecture is crucial for architects, designers, and anyone interested in the built environment. By delving into the technical, aesthetic, and sustainable aspects of ceramics in architecture, we can appreciate the significant impact of production methods on their ultimate architectural application.

Understanding Ceramics in Architecture

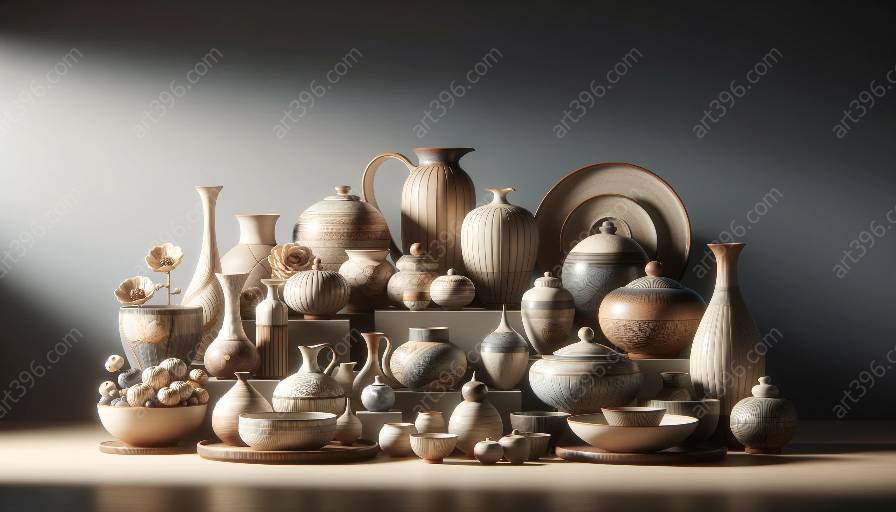

Ceramics, as a versatile and durable material, have been used in architecture throughout history. From traditional ceramics such as clay bricks and roof tiles to modern engineered ceramics like porcelain and glass-ceramics, the utilization of ceramics in architecture has evolved over time. The unique properties of ceramics, including their strength, thermal stability, and visual appeal, make them suitable for a wide range of architectural applications, from cladding and flooring to decorative elements and structural components.

The Production Process of Ceramics

The production process of ceramics plays a critical role in determining their properties and suitability for architectural use. Traditional ceramics are typically made from natural materials such as clay, which are molded, dried, and fired in kilns to achieve the desired strength and durability. Advanced ceramic materials, on the other hand, undergo complex manufacturing techniques such as sintering, hot pressing, and glazing to achieve specific characteristics such as translucency, strength, or thermal insulation.

Impact of Production Methods on Architectural Use

The production method employed significantly influences the architectural use of ceramics. For instance, the firing temperature and duration in the production of clay bricks directly impact their compressive strength and water absorption, determining their suitability for structural purposes or decorative cladding. Similarly, advanced ceramic materials like glass-ceramics undergo precise manufacturing processes to achieve specific optical and thermal properties, making them ideal for architectural elements like facades and lighting fixtures.

Environmental Considerations

Understanding the production process of ceramics is also essential from an environmental perspective. The choice of raw materials, energy consumption during firing, and waste management in ceramic production have implications for sustainability in architecture. By embracing innovative production methods that minimize environmental impact, architects and designers can harness the potential of ceramics as a sustainable building material, contributing to greener and more resilient built environments.

Future Directions

Advancements in ceramic production technologies, such as digital fabrication and additive manufacturing, are opening up new possibilities for architectural applications. These developments are enabling the creation of intricate ceramic components with customized geometries and enhanced performance characteristics, thereby expanding the horizons of ceramic use in architecture. By staying informed about the latest production techniques and material innovations, architects can leverage ceramics to realize bold, sustainable, and aesthetically captivating architectural designs.

Conclusion

The production process of ceramics profoundly shapes their use in architecture, influencing their technical properties, aesthetic appeal, and environmental footprint. By recognizing the interplay between ceramics and architecture, and the significance of production methods in this relationship, we can foster a deeper appreciation for the potential of ceramics to enrich the built environment and inspire architectural creativity.