Fluid dynamics simulation plays a crucial role in the design of aerodynamic products, shaping the way engineers and designers approach the development of aircraft, automobiles, and other aerodynamic structures. By utilizing advanced modelling and simulation techniques, innovators are able to gain deeper insights into the complex behavior of fluids and their interaction with moving objects. This revolutionizes the design process, enhancing efficiency, performance, and safety.

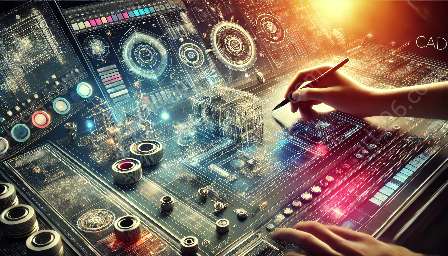

The Basics of Fluid Dynamics Simulation

Fluid dynamics simulation involves the use of computational fluid dynamics (CFD) to analyze how fluids, such as air or water, interact with solid surfaces and structures. This simulation process facilitates the visualization and prediction of fluid behavior, allowing engineers to optimize designs for minimal drag, improved lift, and enhanced stability. Through the use of numerical methods and high-performance computing, engineers can simulate a wide range of scenarios, from airflow over an aircraft wing to water flow around a ship's hull.

Impact on Aerodynamic Product Design

Fluid dynamics simulation has a profound influence on the design of aerodynamic products in various industries. In the aerospace sector, CFD simulations enable engineers to refine aircraft wing shapes, engine nacelles, and other components to achieve optimal aerodynamic performance. This leads to fuel efficiency improvements and reduced environmental impact. Similarly, in the automotive industry, CFD plays a crucial role in designing streamlined vehicle bodies and optimizing flow around key components, resulting in reduced drag and improved fuel economy.

Modelling and Simulation in Design

The integration of modelling and simulation into the design process has transformed the way aerodynamic products are conceptualized and developed. By creating virtual prototypes and subjecting them to fluid dynamics simulations, designers can rapidly iterate through design variations, identifying the most efficient and effective solutions. This approach streamlines the design cycle, reducing the need for physical testing and accelerating time-to-market.

Enhancing Performance and Safety

Fluid dynamics simulation not only influences the external aerodynamics of products but also contributes to enhancing overall performance and safety. By accurately predicting airflow patterns, pressure distributions, and turbulence effects, engineers can minimize the risk of aerodynamic instabilities, improve control characteristics, and enhance the structural integrity of aerodynamic products, ultimately ensuring a safer and more reliable end product.

Future Implications

As advancements in computing power and simulation algorithms continue to evolve, the impact of fluid dynamics simulation on aerodynamic product design will only grow stronger. The ability to accurately capture complex fluid phenomena will drive innovation in product design, opening up new possibilities for efficient, sustainable, and high-performance aerodynamic solutions across various industries.