With the evolution of technology, the field of jewelry design has been revolutionized by the incorporation of digital fabrication techniques. This integration has not only enhanced the design process but has also opened up new horizons for creativity and production efficiency. In this topic cluster, we will delve into the ways in which digital fabrication techniques are transforming jewelry design, from 3D modeling to additive manufacturing, and the impact they have on the overall design landscape.

The Evolution of Jewelry Design

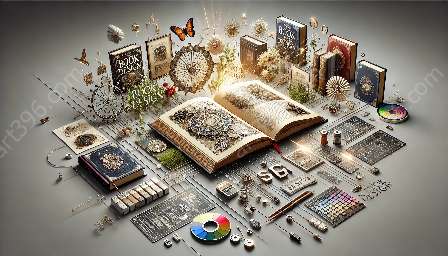

Jewelry design has a rich history rooted in tradition and craftsmanship. Throughout the ages, designers and artisans have employed various techniques to bring their creations to life, from hand-crafting intricate pieces to utilizing casting and molding methods. While these traditional approaches have their own charm, the advent of digital fabrication has introduced a new dimension to jewelry design, blending traditional artistry with cutting-edge technology.

Understanding Digital Fabrication Techniques

Digital fabrication encompasses a range of technologies and processes that enable the transformation of digital designs into physical objects. One of the key components of digital fabrication in jewelry design is 3D modeling. Designers utilize specialized software to create detailed and precise digital models of jewelry pieces, allowing them to explore complex shapes and intricate designs with unparalleled precision.

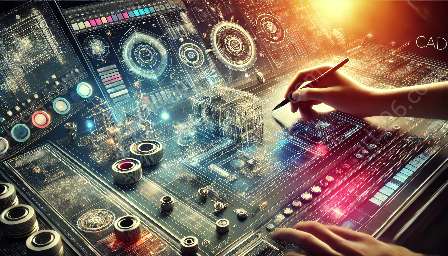

Once the digital model is finalized, digital fabrication techniques such as computer numerical control (CNC) machining and additive manufacturing, commonly known as 3D printing, come into play. These technologies enable designers to translate their digital designs into physical prototypes and finished products, providing greater flexibility and speed in the production process.

Advantages of Digital Fabrication in Jewelry Design

The integration of digital fabrication techniques brings numerous advantages to the world of jewelry design. Firstly, it allows for the creation of intricate and complex designs that would be challenging to achieve through traditional means. With 3D modeling and printing, designers can push the boundaries of creativity, exploring novel forms and textures that captivate the imagination.

Furthermore, digital fabrication techniques enhance the efficiency of the production process. By streamlining prototyping and manufacturing, designers can bring their creations to market faster, reducing lead times and responding more swiftly to evolving trends and customer preferences.

Pushing Boundaries of Creativity

The fusion of digital fabrication and jewelry design is not just about production efficiency; it is also about expanding creative possibilities. Designers can experiment with unconventional materials and innovative structures, leveraging digital tools to transcend the limitations of traditional craftsmanship. The ability to iterate quickly on designs and produce custom, one-of-a-kind pieces empowers designers to realize their artistic vision with unparalleled freedom.

Embracing the Future of Jewelry Design

As digital fabrication techniques continue to advance, the landscape of jewelry design is poised for a transformative future. The convergence of technology and artistry offers endless opportunities for designers to push the boundaries of traditional jewelry design, creating captivating pieces that resonate with contemporary aesthetics. By embracing digital fabrication, the jewelry industry can embark on a journey of innovation and reinvention, ushering in a new era of creativity and possibility.