Ceramics play a pivotal role in various industries, from construction to electronics, owing to their unique properties and versatility. One of the critical factors influencing the strength of ceramic materials is the firing process, which significantly impacts their mechanical properties.

Introduction to Ceramics

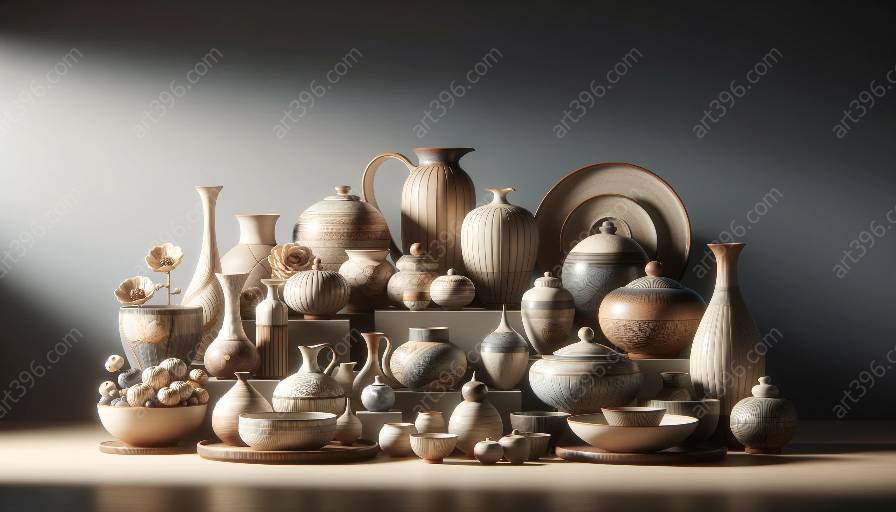

Ceramics, derived from the Greek word 'keramos' meaning potter's clay, encompass a broad range of inorganic, non-metallic materials that are typically crystalline in nature. These materials are known for their excellent thermal and electrical insulating properties, as well as their high melting points, making them indispensable in numerous applications.

Understanding the Firing Process

The firing process is a crucial step in ceramic production, where raw ceramic materials, such as clay, are transformed into the final ceramic product through controlled heating. During firing, the clay particles fuse together, forming a dense, solid structure. The temperature, duration, and heating/cooling rates during firing profoundly influence the microstructure and properties of the ceramic material.

Mechanical Properties of Ceramic Materials

Ceramic materials exhibit remarkable mechanical properties, including high compressive strength, hardness, and resistance to wear and corrosion. However, their brittleness and low tensile strength have limited their use in certain applications. The firing process plays a pivotal role in tailoring the mechanical properties of ceramics, such as their strength, toughness, and thermal shock resistance.

Impact of Firing Process on Strength

During firing, the raw ceramic particles undergo significant physical and chemical transformations, resulting in the formation of a cohesive ceramic structure. The temperature and duration of firing directly influence the degree of densification and crystal growth, ultimately impacting the strength of the ceramic material. Additionally, the cooling rate after firing can also affect the microstructure and, consequently, the strength of the final product.

Real-world Applications

The strength of ceramic materials, influenced by the firing process, is crucial in various practical applications. From high-strength ceramic components in aerospace technologies to durable ceramic tiles in construction, understanding and controlling the firing process is essential for producing ceramics with the desired strength and reliability.

Conclusion

The firing process significantly affects the strength and mechanical properties of ceramic materials, making it a critical aspect of ceramic production. By comprehensively understanding the impact of firing on ceramics, we can facilitate the development of advanced ceramics tailored for diverse applications, thus showcasing the integral role of ceramics in modern industries.